Roller Lubrication: Quietly Transforming Noisy Garage Door Repairs

Garage doors, while convenient, can cause unwanted noise due to worn-out moving parts like springs,…….

Garage doors, while convenient, can cause unwanted noise due to worn-out moving parts like springs, cables, rollers, and bearings. Regular maintenance, particularly lubricating rollers with high-quality lubricant, is crucial for garage door repair. This reduces friction, minimizes noise levels, prevents wear and tear, and prolongs the lifespan of the door system, ensuring silent, smooth, and reliable operations while saving on repair costs.

Roller lubrication is a simple yet powerful solution for reducing noisy garage door operations. Understanding garage door noise and its impact on both comfort and safety is crucial. This article delves into the science behind garage door noise, exploring how roller lubrication plays a vital role in minimizing friction and maintaining smooth, quiet functions. For effective garage door repair and maintenance, adopting this practice can significantly enhance your home’s ambiance and security.

- Understanding Garage Door Noise and Its Impact

- The Role of Roller Lubrication in Reducing Noise and Maintaining Smooth Operations

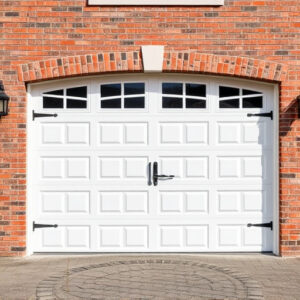

Understanding Garage Door Noise and Its Impact

Garage doors, while convenient for entering and exiting your home, can sometimes create unwanted noise that disrupts peace and tranquility. Understanding the source of this noise is key to addressing it effectively. Garage door operations involve numerous moving parts—springs, cables, rollers, and bearings—that must work in harmony for smooth movement. Over time, these components can wear out, leading to friction and grinding sounds as they interact with each other during opening and closing cycles.

This noise not only disturbs residents but also indicates potential issues within the door’s mechanism. Left unaddressed, worn-out parts may lead to more serious problems like broken springs or damaged tracks, resulting in costly garage door repairs. Regular maintenance, including periodic lubrication of rollers, can significantly reduce such noises and prolong the lifespan of your garage door system.

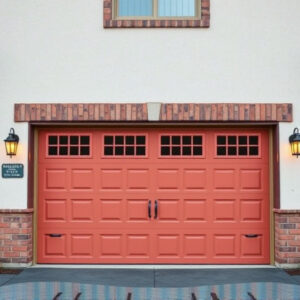

The Role of Roller Lubrication in Reducing Noise and Maintaining Smooth Operations

Roller lubrication plays a pivotal role in garage door repair, significantly minimizing noise levels and ensuring smooth operations. Over time, the metal rollers that support the door’s weight experience friction, leading to increased noise and potential performance issues. Regular lubrication breaks down this friction, allowing the rollers to glide effortlessly along their tracks. By applying a thin coat of high-quality lubricant, you create a barrier between the moving parts, reducing wear and tear, and consequently, the garish creaking or grinding noises.

Maintaining proper roller lubrication is an easy yet effective preventive measure for garage door owners. It prevents costly repairs and enhances the door’s overall functionality. When done correctly, lubrication ensures the door opens and closes silently, smoothly, and reliably, providing peace of mind and a tranquil environment for homeowners. Regular checks and top-ups of lubricant can prolong the lifespan of your garage door system, making it an essential practice in garage door repair and maintenance routines.

In conclusion, addressing garage door noise through roller lubrication is a straightforward yet effective strategy for homeowners. By regularly lubricating the rollers, you can significantly reduce noisy operations and extend the lifespan of your garage door, thereby saving you from costly Garage Door Repair issues down the line. This simple maintenance step ensures a quieter, smoother functioning door, enhancing both comfort and safety in your home’s entranceway.